Fiberglass Ht52h: Comprehensive Guide to Features and Applications

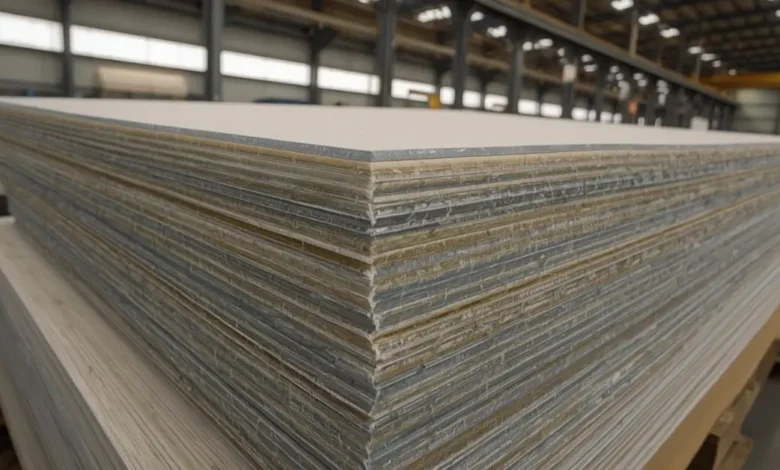

Fiberglass ht52h is a high-performance material that has gained widespread recognition across industrial, commercial, and specialized applications due to its unique combination of strength, durability, and versatility. Unlike conventional fiberglass, ht52h is engineered to withstand high temperatures and demanding mechanical stress while maintaining structural integrity. This makes it an ideal choice for industries that require materials capable of enduring extreme conditions without compromising performance or safety. Its adoption has expanded over the years as more industries seek reliable materials for high-stakes applications.

The development of fiberglass ht52h reflects advancements in material science aimed at enhancing fiber-reinforced composites. By combining specific resins with high-quality glass fibers, ht52h achieves superior heat resistance, tensile strength, and impact resilience. This material stands out not only for its mechanical performance but also for its resistance to chemical corrosion and environmental degradation. As industries such as aerospace, automotive, and construction demand stronger yet lightweight alternatives, fiberglass ht52h has emerged as a go-to solution.

Understanding fiberglass ht52h is essential for engineers, manufacturers, and designers looking to optimize product performance. Its properties influence design decisions, safety standards, and long-term maintenance planning. Moreover, knowledge of its applications and limitations ensures that the material is used effectively, avoiding potential failures or inefficiencies. This article explores fiberglass ht52h in detail, highlighting its features, applications, maintenance practices, and market insights to provide a comprehensive resource for professionals and enthusiasts alike.

Key Features and Specifications of fiberglass ht52h

Physical and Chemical Properties

Fiberglass ht52h exhibits remarkable physical and chemical properties that set it apart from traditional fiberglass. Its high tensile strength and stiffness make it resistant to deformation under load, while its lightweight nature enables easy handling and integration into complex designs. The material’s heat resistance allows it to function efficiently in environments exceeding conventional thermal limits, making it suitable for high-temperature industrial applications.

Chemically, fiberglass ht52h demonstrates exceptional resistance to corrosion, moisture, and a wide range of chemicals. This quality is particularly valuable in industries where exposure to aggressive substances is common, such as chemical processing plants or marine environments. The combination of durability and chemical stability ensures that products made from ht52h maintain their structural integrity and appearance over long periods, reducing maintenance costs and enhancing longevity.

Mechanical Performance

The mechanical performance of fiberglass ht52h is among its most celebrated characteristics. It offers superior load-bearing capacity, excellent impact resistance, and minimal deformation under stress. These properties make it an ideal choice for components subjected to high mechanical loads or dynamic forces. Its flexibility allows for slight bending without cracking, which is essential in applications where vibration or thermal expansion occurs.

Moreover, ht52h performs consistently across a wide range of environmental conditions. Whether exposed to extreme heat, humidity, or varying pressure levels, it maintains its mechanical integrity. This stability ensures predictable performance, which is critical in industries where safety and precision are paramount. By offering a reliable combination of strength, flexibility, and resilience, fiberglass ht52h supports innovative designs that were previously limited by the constraints of conventional materials.

Advantages Over Other Materials

Compared to traditional fiberglass and other composite materials, ht52h offers numerous advantages. Its combination of lightweight construction and high strength allows for more efficient structural designs without sacrificing durability. Cost-effectiveness is another benefit, as the material’s long lifespan and low maintenance requirements reduce overall operational expenses.

Additionally, fiberglass ht52h is environmentally friendly, as it can be produced with sustainable manufacturing processes and offers recyclability options in certain applications. The material’s adaptability allows it to meet the specific requirements of different industries, from construction to aerospace, making it a versatile and valuable resource for modern engineering challenges.

Applications of fiberglass ht52h

Industrial Applications

Fiberglass ht52h is extensively used in industrial settings due to its ability to endure high stress, heat, and chemical exposure. Manufacturing plants, construction equipment, and heavy machinery benefit from its strength and durability. Components such as panels, insulation parts, and structural supports made from ht52h withstand continuous operation without significant wear, reducing downtime and maintenance costs.

In engineering applications, ht52h ensures consistent performance even under extreme conditions, which is vital for operational safety and reliability. Its adaptability allows it to be molded into custom shapes and sizes, supporting complex designs while maintaining structural integrity. Industries that rely on precision and resilience often choose ht52h over alternative materials to achieve these outcomes.

Commercial and Consumer Uses

Beyond industrial use, fiberglass ht52h has found a place in commercial and consumer products. Its lightweight nature and heat resistance make it suitable for electronic housings, appliance components, and consumer equipment that require durability without adding unnecessary weight. The material’s aesthetic appeal, combined with its functional properties, ensures that products remain visually appealing while performing reliably over time.

The commercial adoption of ht52h is also influenced by market trends that favor sustainable and long-lasting materials. As consumers demand products that are not only durable but also environmentally responsible, ht52h provides a solution that aligns with these expectations. Its versatility in design and performance makes it a material of choice for modern commercial applications.

Specialized Applications

In specialized fields such as aerospace, automotive, and marine engineering, fiberglass ht52h is highly valued for its performance under extreme conditions. Aerospace components benefit from its lightweight construction combined with high strength, which supports fuel efficiency and safety. In automotive applications, ht52h is used for panels, insulation, and high-stress parts that must endure vibration and temperature fluctuations.

Marine applications also rely on ht52h’s corrosion resistance and structural reliability, especially in harsh saltwater environments. Additionally, research and technological innovations continue to uncover new applications, demonstrating the material’s adaptability and relevance in cutting-edge developments. Its specialized performance capabilities make it indispensable in sectors where conventional materials fail to meet stringent requirements.

Maintenance, Handling, and Safety

Proper Handling and Installation

Handling and installing fiberglass ht52h requires attention to detail to prevent damage and ensure optimal performance. Users should follow guidelines for safe lifting, cutting, and mounting to avoid cracks or structural compromise. Proper storage and transportation are essential to protect the material from moisture, UV exposure, and mechanical stress before installation.

Avoiding common mistakes, such as applying excessive force or improper adhesives, ensures that ht52h components perform as intended. Training and documentation support correct handling practices, contributing to long-term durability and functionality.

Maintenance and Longevity

Maintaining fiberglass ht52h is relatively straightforward due to its inherent durability. Regular inspection for surface damage, cleaning with non-abrasive solutions, and monitoring for wear or deformation prolong its lifespan. Minor repairs can be performed using compatible resins or fillers, preserving structural integrity.

Consistent maintenance ensures that components continue to function effectively, reducing the need for costly replacements. By maximizing the material’s performance through simple preventive measures, organizations can enjoy long-term cost savings and reliability.

Safety Considerations

While fiberglass ht52h is safe to use in most applications, protective measures are necessary during cutting, sanding, or machining, as fine particles can irritate skin or respiratory systems. Personal protective equipment, proper ventilation, and adherence to safety regulations minimize risks.

Compliance with industry safety standards ensures that both workers and products are protected. Awareness of potential hazards and proactive safety practices are essential for maintaining a secure working environment when using fiberglass ht52h.

Cost, Availability, and Market Insights

Fiberglass ht52h is competitively priced considering its performance advantages. Costs vary depending on thickness, size, and supplier, but its durability and low maintenance requirements often make it more economical than alternative materials. Availability is widespread, with suppliers catering to industrial, commercial, and specialized markets globally.

Market trends indicate increasing demand for high-performance, sustainable materials, positioning fiberglass ht52h as a sought-after option for future applications. Innovations in production and distribution continue to improve accessibility, ensuring that engineers and manufacturers can leverage its benefits efficiently.

Conclusion

Fiberglass ht52h is a versatile, high-performance material that offers remarkable strength, heat resistance, and chemical durability. Its applications span industrial, commercial, and specialized sectors, providing solutions for challenging environments and demanding requirements. Proper handling, maintenance, and safety measures ensure long-term performance, while cost-effectiveness and sustainability make it an attractive choice for modern industries. By understanding its features, applications, and best practices, professionals can optimize performance, enhance efficiency, and achieve reliable results with fiberglass ht52h.

FAQs About fiberglass ht52h

What is fiberglass ht52h and what makes it unique?

It is a high-performance fiberglass with superior heat resistance, strength, and chemical durability.

What are the main applications of fiberglass ht52h?

Industrial components, commercial products, aerospace, automotive, and marine parts.

How does fiberglass ht52h compare to other fiberglass types?

It offers higher heat resistance, mechanical strength, and durability.

What are the key advantages of using fiberglass ht52h?

Lightweight, durable, cost-effective, and environmentally friendly.

How should fiberglass ht52h be handled and maintained?

Follow safety guidelines, store properly, inspect regularly, and perform minor repairs as needed.

Is fiberglass ht52h suitable for high-temperature environments?

Yes, it is designed to withstand extreme heat without compromising performance.

Where can I buy high-quality fiberglass ht52h?

Industrial suppliers, specialized distributors, and authorized online retailers.

What safety precautions are needed when handling fiberglass ht52h?

Use protective equipment, proper ventilation, and follow regulatory standards.

How long does fiberglass ht52h typically last in industrial use?

With proper maintenance, it can last many years, often exceeding the lifespan of conventional materials.

Are there any emerging trends or innovations related to fiberglass ht52h?

Advancements include AI-assisted manufacturing, eco-friendly resins, and improved customization for specialized applications.

You May Also Read: What About Potnovzascut Issues